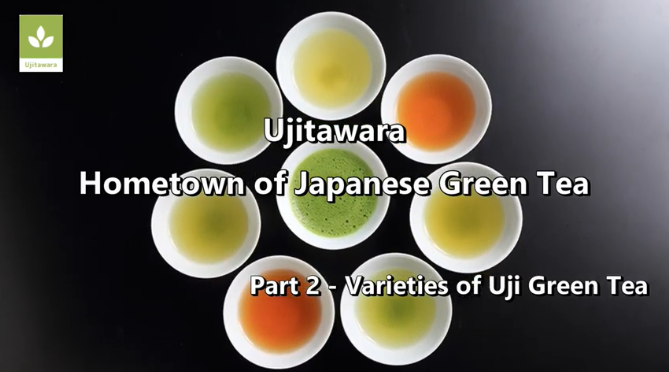

about Uji green Tea

Judging from a comprehensive viewpoint (considering historical, cultural, geographical and climate backgrounds), Uji tea can be defined as green tea that is harvested in either Kyoto, Nara, Shiga or Mie prefectures (which have been developing together in cooperation), processed and finished by tea manufactures in Kyoto Prefecture.

However, the green tea from Kyoto Prefecture shall be given priority over that from the other prefectures.

the Varieties of Uji Tea

gyokuro

Gyokuro is made with the tea leaves that are grown in fields shaded from sunlight after new shoots begin to emerge, or about 3 weeks before the tea-picking season. Blocking sunlight increases chlorophyll content in the tea leaves and turns the color to bright green.

Uji Gyokuro is the highest grade of all Japanese green tea varieties. After drinking, a mellow and rich taste is left in your mouth.

kabusecha

Kabusecha is made with the tea leaves that are grown in plantations covered with straw or cheesecloth (covered cultivation) to screen the sunlight for about a week. It combines the flavor of Uji Gyokuro and the refreshing taste of Uji Sencha.

sencha

Sencha is the most commonly used green tea variety. It is a “non-fermented tea” that is prepared by deactivating oxidase enzymes through a heat treatment process. The beauty of Sencha is the refreshing aroma and refined astringent taste. You will feel a cool sensation after drinking.

matcha

Matcha is green tea powder ground in a stone mortar. It is made with the tea leaves that are steamed and then dried without the rolling process. Enjoy the rich and mild sweetness of Matcha.

karigane

Karigane consists of stems and stalks that are removed during the manufacturing process of Uji Gyokuro and Uji Sencha. It is characterized by the distinctive taste of stems.

genmaicha

Genmaicha is a blend of Uji tea with roasted brown rice. Enjoy the fragrant aroma of brown rice combined with the refreshing taste of Uji Sencha.

hojicha

Hojicha is composed of Uji tea leaves that are roasted at a high temperature to bring out the rich aroma. It is gentle to the body because of the low caffeine content, so recommendable for small children and elderly people.

Kyobancha

As the name connotates (Bancha means "late harvest tea"), Kyobancha is made with fully grown up tea leaves. “Bancha” in general is processed by kneading the old tea leaves, but“Kyobancha”, or Bancha produced in Kyoto, is made in a different way. The tea leaves are firstly steamed, then dried without the kneading process, and after that roasted like Hojicha. A lot of fragmented leaves and stems can be found in Kyobancha. Kyobancha has a fragrant aroma.

Uji greentea

How to brew uji tea

1. Put the following amount of tea leaves into a teapot.

Approximately 2 grams per person (for Sencha)

Approximately 3 grams per person (for Gyokuro)

2. Boil water

Boil water for about 5 minutes. Then let the water cool down to the appropriate temperatures as indicated below.

When hot water is poured into a teapot, its temperature drops by approximately 10 degrees. In turn, the teapot becomes warm, thereby enhancing the taste of tea.

Appropriate water temperatures:

70 ℃ (for Sencha)

50 ~ 60 ℃ (for Gyokuro)

3. Pour brewed green tea into teacups in turn

Put hot water at the recommended temperature into the teapot with tea leaves in it. Then, pour the brewed tea into each teacup little by little in turn, until the teapot is empty.

uji tea processing method

Uji Tea Manual Rolling Techniques

Tea leaves for Sencha and Gyokuro harvested by hand or shears are processed through a series of steps. Nowadays, most of the steps is done by machines, but this whole process was originally devised based on the principle of manual tea rolling.

The manual-rolling tea production method was devised in 1738 by Nagatani Soen, a tea farmer in Ujitawara. Green tea prepared with this method was superior in terms of color, aroma and flavor, compared to the conventional one, so it spread out across the nation and became the basis for today’s Uji tea processing method. The valuable technique has been preserved and passed on as an intangible cultural asset by Uji-cha Tea Production Method Preservation Association.

In 2009, the effort to preserve the traditional technique was acknowledged by the Kyoto Prefectural Board of Education, and it was designated by Kyoto Prefecture as an Intangible Folk Cultural Property.

Uji tea manufacturing process

The tea leaves for Uji tea is cultivated with great attention and care, and processed accordingly into each green tea product.

The principle of the traditional manual tea rolling has been studied and tested to replicate the process. Today, the automation of almost the whole process from steaming to drying is achieved.

The Steps of Manual Tea Rolling

|

Steaming |

The tea leaves are laid out on seiro (bamboo steamer basket) which is placed on koshiki (wooden steaming basket), and steamed with boiling water in an iron pot under the koshiki. The leaves are mixed with long chopsticks during this process so that they are steamed evenly. Once the smell of steam has changed, seiro is moved from koshiki to a cooling table to cool down the leaves sufficiently.

|

|

Tsuyukiri (Shaking off moisture) for

About 25 minutes |

The leaves that are cooled down are laid out on jotan (a frame spanned by Japanese paper) that is set on hoiro (a table for tea rolling and drying). The leaves are picked up by hand, and then thrown off from a height of 30 to 40 cm to reduce the moisture content of the surface. |

|

Yokomakuri (Rolling)

for About 1 hour 30 minutes |

The leaves are rolled and kneaded with both hands from side to side. Then, the leaves are slowly rolled and kneaded in all directions, putting weight on the hands. The moisture content of the leaves is reduced to about 50%.

|

|

Tamatoki (Loosening chunks) for about 5 minutes |

Chunks of leaves that were generated during yokomakuri are loosened and unraveled by stirring the leaves in all directions using your fingers like a rake. |

|

Nakaage (Cooling down) for

About 10 minutes |

The leaves are taken out of jotan, and then spread out thinly and evenly on a shallow basket to let them cool down. Meanwhile, tea incrustation on the jotan’s surface is wiped off. |

|

Chazoroe or Momikiri (Kneading) for

About 30 minutes |

This process requires special expertise. The tea leaves are twisted back and forth between the palms. This is done in a way that the leaves that are being kneaded come out both upwards and downwards. |

|

Denguri (Pressing) for

About 20 minutes |

The tea leaves are put together in the center of jotan, and held from both sides with both hands. The leaves are rubbed against each other between the palms, supported by one hand below and pushed them with other hand above. Through this step, the shape of tea leaves is adjusted, taking on the appearance of fine needles. |

|

Itazuri (Rubbing) for

About 50 minutes |

The leaves are put aside into a corner of jotan whereas the remaining powder is pasted on the jotan’s surface to keep it from slipping. Then, a wooden board is installed on jotan and the leaves are placed on it. Aligned in the same direction, the leaves are rolled and rubbed up and down with both hands, so that they get straight and shiny. |

|

Drying for

About 40 minutes |

The leaves are thinly and evenly laid out on jotan to be dried at a low temperature (60°C) until the moisture content is approximately 4 percent. The leaves are then left to cool down and put into storage. |

Things to Do Before Harvest

Tea production begins before harvesting the leaves

Tea contains a substance called theanine. It is an amino acid that brings out the umami flavor of green tea. Theanine is synthesized in the root of tea plant and then reaches the leaves where it is transformed into the catechin, an astringent ingredient of tea, under the influence of sunlight. Gyokuro and Tencha are made with tea leaves grown without sunlight exposure, which is why they both taste mellow. Specifically, the tea leaves are covered with reed blinds, straws, chemical fibers and the like, so that they are shaded from sunlight.

The cultivation method in which the tea leaves are covered with reed blinds is passed down from ancient times in the production areas for Uji green tea. Reed blinds are laid out on shelves made with logs and bamboo, and straw is spread over them. Because of the low temperature and high humidity inside the tea garden, tea sprouts grow slowly.

In oishita-en, chemical fiber that resembles reed blinds is used to cover steel frame shelves. It has two tiered covering structure to increase air permeability and prevent the rise of temperature inside the tea garden.

Tea trees for Gyokuro is covered about 20 days before harvest to block the direct sunlight. Tea trees for Kabusecha is covered for a shorter period of time than those for Gyokuro. Because of this, Kabusecha has the flavor combining the richness of Gyokuoku and the refreshingness of Sencha.

The flavor of tea varies depending on the environment where it is planted. The majority of tea plants cultivated in Japan are a cultivar called Yabukita , which is characterized by its high ability to absorb nutrients. It can be said that the flavor of tea reflects the soil and water of the land it is grown in. The reason that the same tea cultivar can taste different is that soil properties are different according to the production area and tea garden. This, in turn, gives us more fun to explore our favorite tea varieties.